Machine ranges

HERCULE machines

Hydraulic and Hybrid injection molding machines

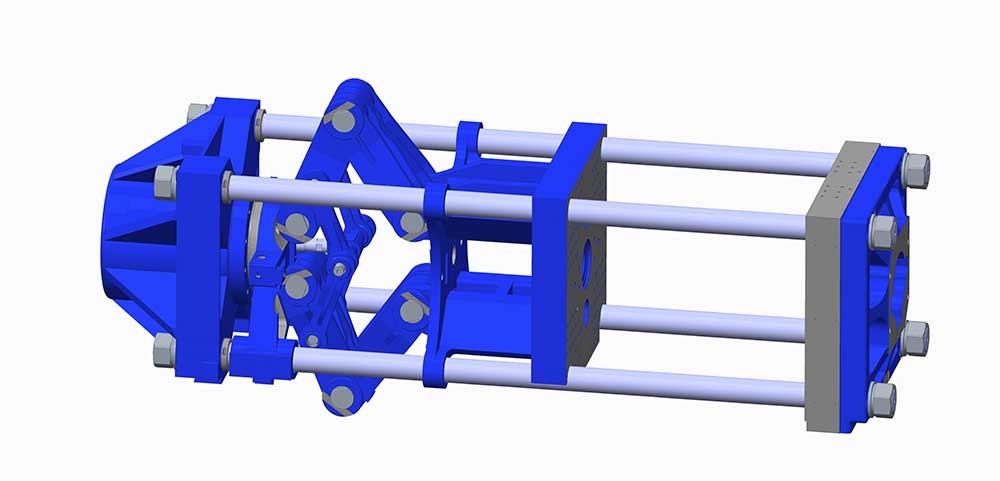

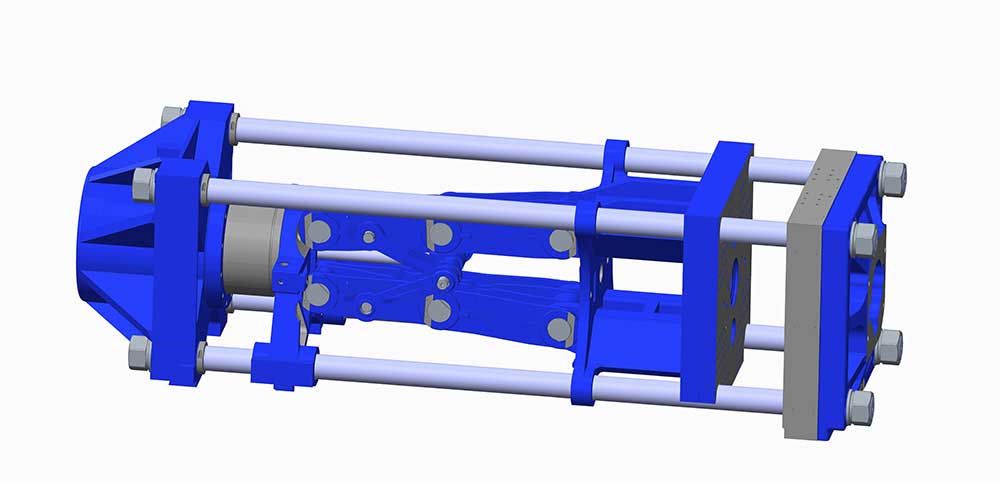

- Closing unit with double toggle and hydraulic clamping cylinder.

A range of powerful machines for a great variety of applications.

HERCULE Range 200 to 320 Tons

HERCULE range responds to the needs of plastics processors seeking improved productivity, accuracy, flexibility and versatility.

These multi-purpose machines are available in full hydraulic or hybrid versions, in single and multi-injection and suitable for materials such as Thermoplastics, PVC, LSR, Composites…

Hydraulic system with accumulators

The accumulator based hydraulic system with fixed displacement pump(s) promotes rapid simultaneous movements and high injection rates.

The energy stored in the accumulators satisfies peaks of oil demand, reducing the installed power requirement and energy consumption.Read more

Clamping unit with double toggle and hydraulic cylinder

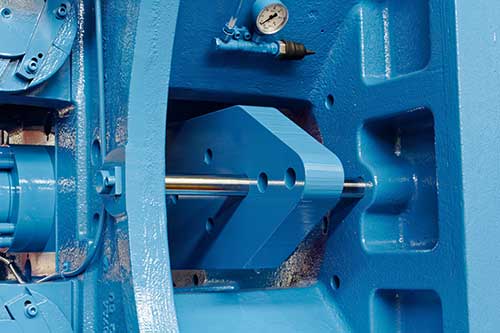

The HERCULE clamping unit movement is activated by a small centrally mounted hydraulic piston driving the toggles.

The double toggle amplifies the motion with natural acceleration and deceleration, providing smooth high mold movement speeds with minimal energy consumption.

- Precise locking controlled by sensor Read more

- Mold environment Read more

- Perfect mold alignmentRead more

Mold environment

Expansion and contraction of the mold are fully compensated by the system to provide a consistent locking force and precise mold safety.

Mold environment

- Generous ejector box equipped with a wide plate to enable multipoint connection of the ejectors

- The front and rear mold guards feature a wide opening stroke and no upper rail to simplify mold access.

Perfect mold alignment

The perfect mold alignment is assured by :

- Generous guide length for moving platen bushes

- Fixed mold supports under the tie bars

- Durable low maintenance structure